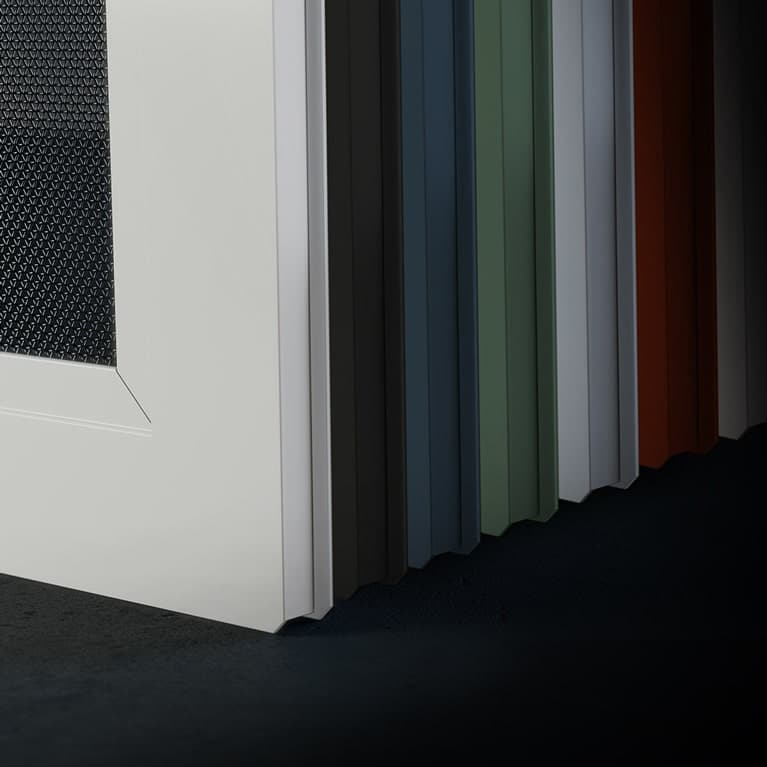

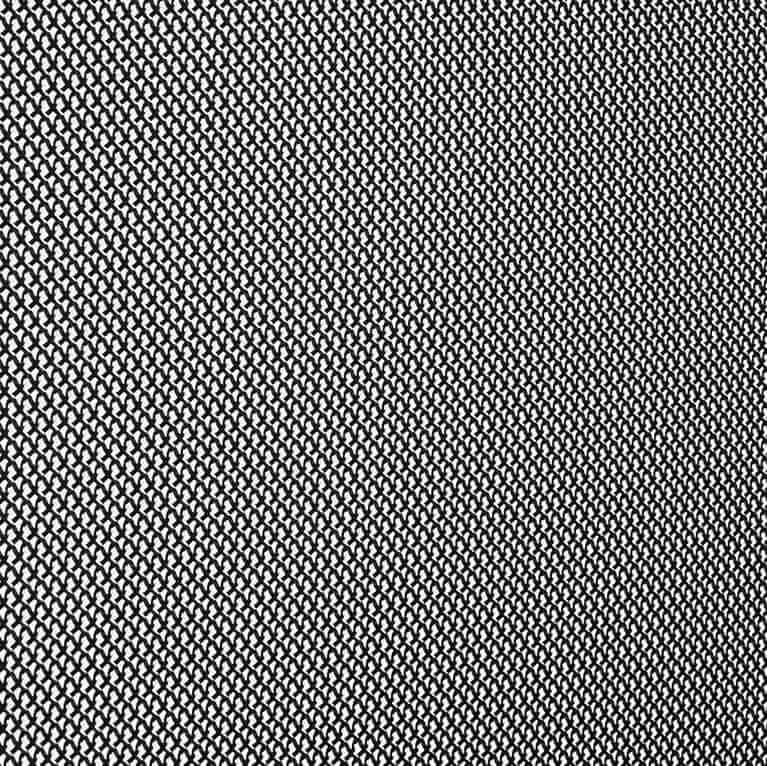

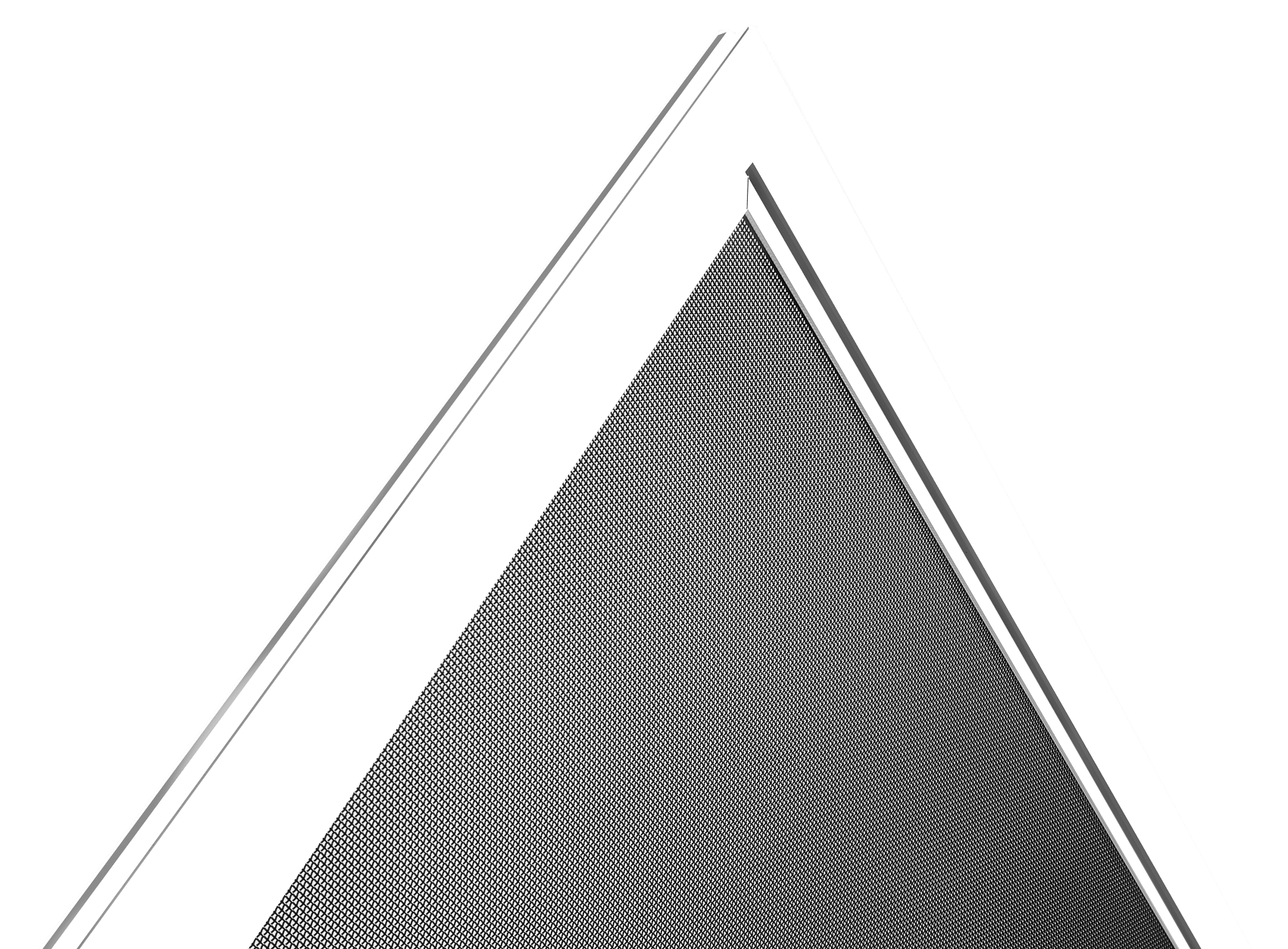

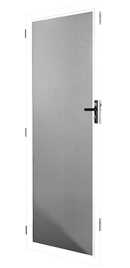

ForceField security doors and window screens are welded instead of being held together by screws or rivets. A weld is stronger than any screw or rivet…and it looks better too. With its seamless corners, ForceField is the best looking security screen on the market. The heavy duty aluminium frame and the genuine Meshtec marine grade stainless steel mesh are joined together in a mechanical and chemical bond. It is virtually unbreakable and provides complete insulation of the two metals…eliminating a major cause of corrosion. ForceField has passed every imaginable test – and a few you would never imagine.

Explore